1. Preface

In the next few years, the Federal Waterways and Shipping Administration (WSV) intends to replace a number of weirs on their waterways. For the movable weirs, a change in the gate system is planned to water-filled rubber gates. The movable weirs on the rivers Neckar, Main and Lahn are already in the planning stage. Three weir spans, each up to 40 m in width, are to be built on the Main river and on the Neckar river. Two weir spans, each between 18 and 25 m, are to be built on the Lahn river. The gate heights vary between 3.50 m and 4.60 m.

For these projects, only water-filled rubber gate systems (combination of membrane and clamping system) may be used which meet the requirements in a prequalification process prior to execution. The construction company is responsible for the selection of a rubber gate system for the project from the listed prequalified rubber gate systems.

Against this background, suppliers of rubber gate systems are requested to participate promptly in a corresponding prequalification procedure for their respective rubber gate systems.

2. Rules and requirements

A comprehensive guideline for the design, construction and maintenance of rubber gates is currently not available. The Federal Waterways Engineering and Research Institute (BAW), as a higher authority in the portfolio of the Federal Ministry of Digital Affairs and Transport (BMDV) and as consultant and advisor for the WSV, has the goal to develop a Code of Practice comprising five parts on hydraulics, load-bearing capacity, construction materials, construction and commissioning and maintenance. Part B, which which was published in 2019 and addresses the structural analysis of the membrane, has to be revised and supplemented with information on the verification of the load-bearing capacity of the clamping line construction. A first draft version of the Code of Practice sections A (Hydraulic Design), C (Materials and Verification of Functionality), as well as the revised section of Part B concerning the clamping system, was published in August 2023 (https://izw.baw.de/wsv/planen-bauen/gelbdruckverfahren). The two remaining sections of the Code of Practice are currently under development. The official adoption of the complete Code of Practice will take place following an initial testing phase within the WSV.

The relevant membranes are composite materials consisting of an elastomer made of the base polymers EPDM or CR and fabric made of polyester and polyamide. The membrane must meet defined requirements in terms of load-bearing capacity (tensile strength for load transfer from internal pressure, etc.), durability (heat and ozone aeging, etc.), environmental compatibility (release of environmentally dangerous substances), and health and safety.

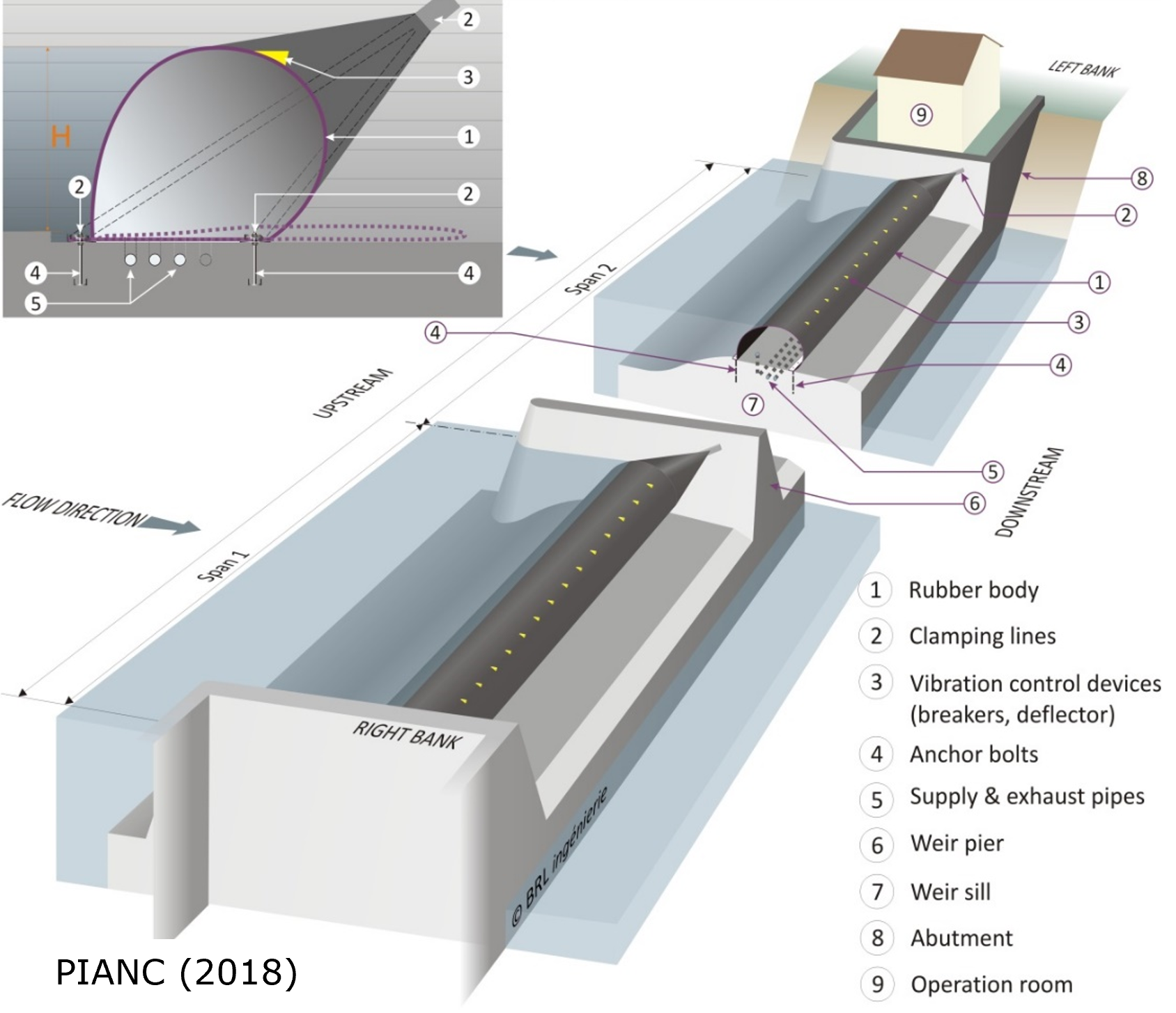

The membrane must be tightly connected by the clamping lines to the reinforced weir body and the weir piers. This is in order to transfer the water loads and the operating pressure into the weir body. In general, steel rails are used for the tension-resistant connection, into which the membrane is clamped. Common clamping lines are connected to the concrete by anchors. The anchors are prestressed in order to hold the membrane in the line and the line itself on the weir body by means of a frictional connection.

The pretensioning force required for the load-bearing capacity of the structure may be reduced due to the creep of the membrane and if the free elongation length of the tension elements is insufficient. Due to the elastic behavior of the rubber an associated drop in the pretensioning force, displacements and / or twisting of the clamping line can generally occur. This leads to additional bending stresses in the tension elements with a possible overload. Against this background, the functionality of the clamping line must be demonstrated analytically. Furthermore, the interaction with the membrane has to be checked and verified by means of a component test.

3. Aim of the prequalification

The aim of the prequalification procedure is to provide the verification of applicability of rubber gate systems, each consisting of a specific membrane in conjunction with a specific clamping line, for movable weirs with different heights on federal waterways, prior to the award procedure. This is intended to counter the risk of problems in the verification of applicability of the rubber gate system to be selected by the respective construction company during construction without, however, restricting the market in a way that does not comply with procurement law.

4. Realisation of the prequalification procedure

Against the background of the projects on the rivers Main, Neckar and Lahn, which are already in the planning stage, the prequalification procedure should take place as soon as possible.

Interested suppliers for a dialogue are requested to contact us promptly. In the dialogue, further information on the prequalification procedure and the criteria will be given. Pre-qualifications completed by December 31, 2026, are eligible for a cost contribution of €25,000 under the terms of the cooperation.

The prequalification procedure is sponsored by the Federal Waterways and Shipping Administration (WSV) and the Federal Waterways Engineering and Research Institute (BAW). Since the planned weirs are to be used on different sites on the German waterways, the WSV is represented by the General Directorate for Waterways and Shipping (GDWS).

Contact details

GDWS: BAW:

Markus Feltgen Dr. Amir Rahimi

markus.feltgen@wsv.bund.de amir.rahimi@baw.de

+49 228 7090 5851 +49 721 9726 4385

Verfasst von Amir Rahimi

- Web |

- More Posts(2)